Latex dispersions

In a historical sense, latex particles are natural products which can be found as polymeric materials in more than 2000 kinds of plants. The most important material in this connection is natural rubber. Nowadays all types of polymer dispersions are called latex. Polymer dispersions are colloidal systems consisting of particles with various morphologies.

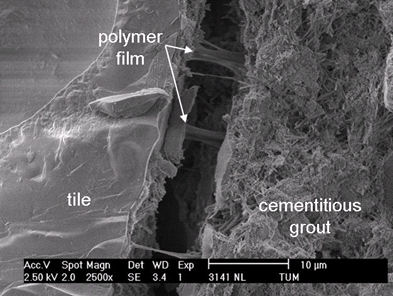

Aqueous polymer dispersions are used in the field of construction chemicals mainly for modification of cementitious mortars and concrete. After hardening, pure cementitious mortars are hard, brittle and show little adhesion, particularly if applied in thin beds (e.g. tile mortars, Fig.1). Through the addition of polymer dispersions, adhesion, flexible strength or consistency of the structure can be improved. Furthermore, dispersions enhance flexibility and abrasion resistance of cementitious systems.

Fig. 1: Adhesion of a sintered tile on cement mortar by latex film bridging (SEM recording – hardening: 28 days).

Dispersions are used as mortar admixtures in glues for construction, tiles and thermal insulation compound systems as well as in screed pastes and plasters. One component dry mortars including redispersible dispersion powders, which are obtained through spray drying from aqueous polymer dispersions, have gained increasing importance in application. These mortars possess a high application assurance since all components such as binder, fillers and admixtures are ex factory fixed and premixed under defined conditions.

The synthesis of polymer dispersions is mostly carried out through emulsion polymerization. This radical polymerization is carried out in the presence of surfactants and in water as the dispersing agent. The properties of polymer dispersions can be tailored according to the desired requirements by co-polymerization of various monomers.

Because of their ability to form a film, dispersions can be classified as polymeric binders. By the elimination of water the polymer particles get in contact with each other and upon further elimination of water the particles become deformed and a polymeric film is developed (Fig. 2).

Fig. 2: Polymer film formation from an aqueous latex dispersion.

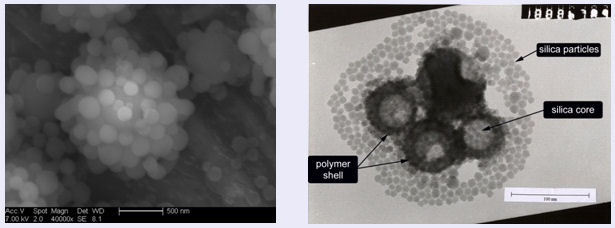

At the chair for construction chemicals polymer dispersions of different compositions and particle morphologies are synthesized and characterized. Besides purely organic systems also inorganic-organic hybrid systems are investigated (Fig. 3).

Fig. 3: Raspberry structured latex particles synthesized via stepwise heterocoagulation (left; SEM recording). Inorganic-organic hybrid particle using a silica sol as inorganic component (right; TEM recording).

The polymer dispersions and nanoparticles were analyzed by dynamic light scattering (DLS), zeta potential measurements, streaming current measurements and electron microscopy (ESEM, SEM, TEM).

Another main research area is represented by investigations of the interactions of polymer dispersions with cementitious systems.